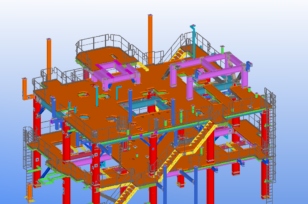

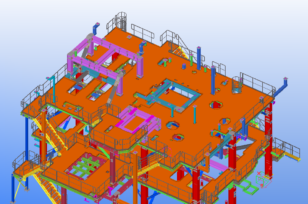

TMETAL won an order for a steel structure to Norway. It will be a part of a device for capturing and storing CO2 from the Norcem cement plant in Brevik. Our company supplies steel structures for the compressor system (railings, stairs, ladders, footbridges). We supply approx. 160 tons of steel structures, including design and statics.

This unique project to build a CO2 capture, liquefaction and temporary storage facility at the Brevik cement plant will be the first large-scale facility of its kind in the world, supported by the Norwegian government. It is supposed to capture approximately 400,000 metric tons of CO2 annually and thus reduce emissions from cement produced in Brevik by 50%. It will separate the CO2 using a solvent and divert it to underground storage, where it will be temporarily stored and then transported by ship to permanent storage under the seabed on the west coast of Norway. The cement plant in Brevik will also be the first to use a special technology to recover heat coming from the compressor system and use it as steam to cover approximately one third of the plant’s total heat demand. As a result, the system solution requires significantly less energy compared to conventional carbon capture technologies.

The aim is to start separating CO2 from the cement production process in Brevik by 2024. As cement plants are one of the biggest emitters of CO2, capturing CO2 in cement plants is considered a crucial step towards achieving climate goals

Category: Investment constructions

Destination country: Norway

What they say about us

“ We were very happy with the technical solution and the delivery of technological and supporting steel structures for the hydrogen production units by the company TMETAL. We are looking forward to continued cooperation. “

Petr Pazdera, ZVU Engineering a.s., Hradec Králové

© 2024 TMETAL Strong in steel processing

© 2024 TMETAL Strong in steel processing